https://www.calahan.com/wp-content/uploads/2025/08/How-Commercial-Building-Additions-Impact-Property-Value.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2021/02/ccs_logo_full.png

AbstraktMarketing2025-08-11 10:37:342025-10-18 14:23:55How Commercial Addition Planning Impacts Property Value

https://www.calahan.com/wp-content/uploads/2025/08/How-Commercial-Building-Additions-Impact-Property-Value.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2021/02/ccs_logo_full.png

AbstraktMarketing2025-08-11 10:37:342025-10-18 14:23:55How Commercial Addition Planning Impacts Property ValueMetal vs. Conventional Construction: Which Fits Your Project?

When planning a new facility or expansion, choosing the right building method is one of the most important decisions you’ll face. This blog breaks down the differences between metal vs. conventional construction, helping you compare costs, timelines, design flexibility, and long-term performance. Whether you’re building a warehouse, office, or mixed-use facility, we’ll help you understand your options and make a more confident, informed choice.

The Main Types of Commercial Building Construction

Choosing the right building method is a foundational step in any commercial project. The approach you take affects everything from construction timelines to long-term costs and design flexibility.

There are four primary types of commercial building construction to consider:

- Pre-engineered metal buildings, known for speed and efficiency

- Tilt-up concrete, ideal for large, flat-site projects

- Masonry or block construction, often used for durability and aesthetics

- Conventional steel or wood framing, offering traditional flexibility

Understanding the key differences between metal vs. conventional construction methods is the first step in making a decision that aligns with your timeline, budget, and operational goals.

Speed and Scheduling Considerations

Construction timelines are often the driving force behind project decisions. If time to occupancy is a top priority, some methods clearly outpace others. Here’s how metal vs. conventional construction methods compare when it comes to build speed.

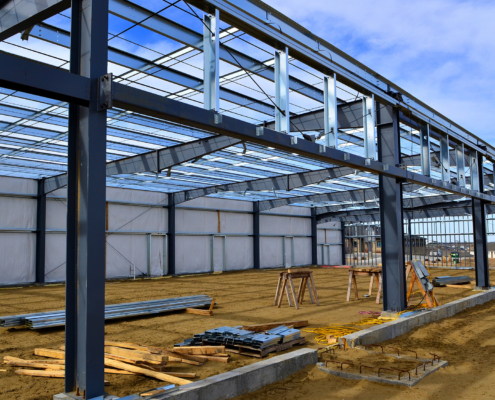

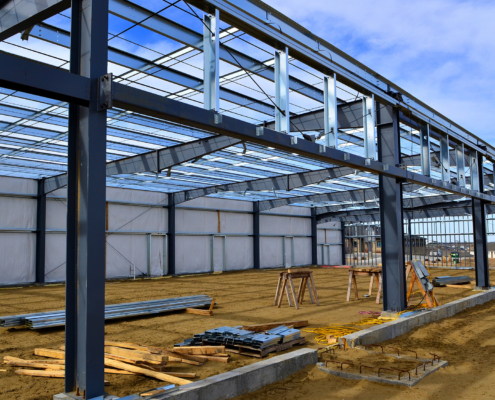

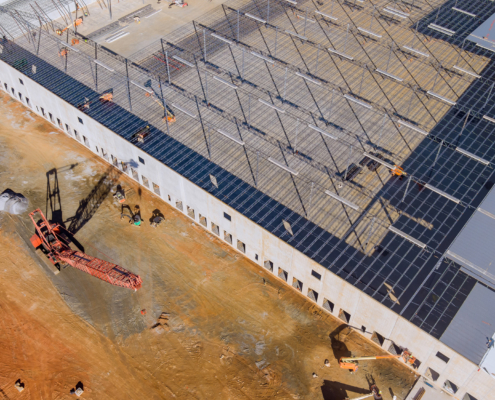

Pre-Engineered Metal Buildings

Pre-engineered metal systems are manufactured off-site and delivered ready for assembly. That means less site work, faster erection, and fewer weather delays. With fewer trades required and tighter quality control, these projects often reach completion in a fraction of the time.

Tilt-Up Concrete

Tilt-up panels are poured onsite and raised into place, allowing for quick enclosure once the foundation is ready. However, the speed depends heavily on weather, concrete cure times, and the availability of specialized crews and equipment.

Masonry and Block Construction

Brick and block walls are built course by course, which makes this method slower, especially in poor weather. Staging and scaffolding also extend the schedule. Masonry is durable but time-intensive.

Conventional Framing

Traditional steel or wood framing can be efficient when well-coordinated, but it involves multiple trades working in sequence. Each phase—framing, sheathing, and exterior finishing—adds time, making this one of the slower options for large-scale commercial projects.

Cost Comparison for Building Methods

Budget is always top of mind, and understanding how each method affects both upfront and long-term costs is essential for smart planning. Here’s a construction method comparison to help:

Pre-Engineered Metal Buildings

Metal building cost savings come from material efficiency, reduced labor hours, and faster build times. There’s less waste, less weather downtime, and often lower maintenance over the life of the building. Total installed cost is typically lower than conventional alternatives, making this a top contender for cost-effective commercial construction.

Tilt-Up Concrete

Tilt-up costs are generally lower than masonry but higher than metal buildings. They require a large, flat site and specialized crews. Labor costs are more predictable than masonry, and speed can help reduce overall construction expenses, though upfront concrete and rebar costs can be significant.

Masonry and Block Construction

Masonry is one of the most expensive options due to material and labor intensity. Skilled masons are in short supply in many markets, which drives up pricing. Maintenance and energy efficiency can offset some costs over time, but it’s rarely the most affordable choice for basic commercial use.

Conventional Framing

Conventional framing costs vary widely depending on structural needs, finishes, and local labor rates. Material prices fluctuate, especially for steel, and the need for multiple subcontractors increases complexity and cost risk.

Design Flexibility and Limitations

Some owners worry that choosing a faster or more affordable method limits their design options. Here’s how each stacks up in terms of flexibility and aesthetics.

Pre-Engineered Metal Buildings

Metal buildings have come a long way in terms of design. Today, they support open interiors (thanks to clear-span construction), modular expansions, and a variety of exterior finishes like brick, stucco, or glass. The main limitation is in high-end architectural detailing, but many owners find the trade-offs worthwhile for operational spaces.

Tilt-Up Concrete

Tilt-up offers moderate design flexibility. Panels can be customized with reveals, embedded materials, or colored finishes, but window placement and architectural elements are limited by the panel system. It’s great for clean, modern aesthetics in spaces like warehouses and industrial buildings.

Masonry and Block Construction

Masonry shines when appearance matters. It supports intricate detailing, varied textures, and timeless aesthetics. It’s a strong fit for institutional buildings, schools, or applications where curb appeal is paramount.

Conventional Framing

Conventional builds offer the highest flexibility for custom layouts and complex rooflines. They support virtually any architectural style and interior configuration. For high-end office or mixed-use projects, this method often offers the most creative freedom.

Explore how an experienced general contractor can help you compare options, manage costs, and align your build with long-term goals—no matter the construction method you choose.

Tilt-Up vs. Metal Buildings: A Closer Look

When comparing tilt-up vs. metal buildings, the right choice depends on your priorities, including speed, appearance, site conditions, and long-term use.

Tilt-up construction involves casting concrete panels onsite and lifting them into place. It works best on large, flat lots where crews have room to operate. Once poured and cured, panels go up quickly, creating a durable structure with a clean, modern aesthetic. Tilt-up is especially popular for office/warehouse hybrids and buildings with a strong visual presence.

Metal buildings, by contrast, are fabricated off-site and assembled quickly on location. This method significantly reduces build time, labor needs, and weather-related delays. Metal systems are ideal for wide-open interiors like warehouses, light industrial, and vehicle storage, and they offer straightforward expansion opportunities down the road.

In short:

- Tilt-up offers more visual customization and a solid, monolithic appearance.

- Metal buildings deliver faster timelines, lower costs, and flexible layouts.

Both are efficient, proven methods, it’s just a matter of what fits your site, schedule, and end-use best.

Which Construction Method Fits Your Project Goals?

Now that you’ve seen the pros and cons of metal vs. conventional construction, how do you choose the best path forward?

Here are a few key questions to guide your decision:

- Do I need a fast build to hit an opening date or reduce carrying costs?

- Is the site flat, tight, or otherwise constrained?

- Will the building be customer-facing or primarily functional?

- Am I planning to expand or modify the building in the future?

- How important is architectural detailing or branding?

- What’s my long-term maintenance budget?

Answering these questions will help you align your project needs with the right method, whether that’s pre-engineered metal, tilt-up concrete, or something more traditional. There’s no single “best” method, but there is a best fit for your goals, and knowing how to weigh the trade-offs is what ensures you build smarter.

Talk to a Team That Builds Both Ways

Whether you’re leaning toward a metal system or considering a more traditional route, Calahan Construction brings deep experience across all major methods. We help you compare your options based on site conditions, project goals, and long-term value, so you can make the right call with confidence.

Let’s talk about your construction goals—schedule a consultation today.

Share This Post

More Like This

https://www.calahan.com/wp-content/uploads/2025/08/How-Commercial-Building-Additions-Impact-Property-Value.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2021/02/ccs_logo_full.png

AbstraktMarketing2025-08-11 10:37:342025-10-18 14:23:55How Commercial Addition Planning Impacts Property Value

https://www.calahan.com/wp-content/uploads/2025/08/How-Commercial-Building-Additions-Impact-Property-Value.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2021/02/ccs_logo_full.png

AbstraktMarketing2025-08-11 10:37:342025-10-18 14:23:55How Commercial Addition Planning Impacts Property Value https://www.calahan.com/wp-content/uploads/2025/07/Key-Considerations-Before-Starting-a-Warehouse-Expansion.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2021/02/ccs_logo_full.png

AbstraktMarketing2025-07-09 07:13:192025-10-18 14:23:55Key Considerations Before Starting a Warehouse Expansion

https://www.calahan.com/wp-content/uploads/2025/07/Key-Considerations-Before-Starting-a-Warehouse-Expansion.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2021/02/ccs_logo_full.png

AbstraktMarketing2025-07-09 07:13:192025-10-18 14:23:55Key Considerations Before Starting a Warehouse Expansion

Strategies to Reduce Downtime During Your Commercial Construction Project

Commercial Constuction, Remodel/Renovation

What You Should Know About Commercial Building Codes Before an Addition

Additions, Commercial Constuction https://www.calahan.com/wp-content/uploads/2025/01/indoor-sport-facility.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2021/02/ccs_logo_full.png

AbstraktMarketing2025-01-21 19:24:002025-10-18 14:24:00Sports Facility Construction: Everything You Need to Know

https://www.calahan.com/wp-content/uploads/2025/01/indoor-sport-facility.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2021/02/ccs_logo_full.png

AbstraktMarketing2025-01-21 19:24:002025-10-18 14:24:00Sports Facility Construction: Everything You Need to Know https://www.calahan.com/wp-content/uploads/2025/01/Worker-installing-solar-panels-on-roof.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2021/02/ccs_logo_full.png

AbstraktMarketing2025-01-20 12:04:002025-10-18 14:24:00Five Energy-Efficient Construction Techniques You Should Be Using

https://www.calahan.com/wp-content/uploads/2025/01/Worker-installing-solar-panels-on-roof.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2021/02/ccs_logo_full.png

AbstraktMarketing2025-01-20 12:04:002025-10-18 14:24:00Five Energy-Efficient Construction Techniques You Should Be Using https://www.calahan.com/wp-content/uploads/2024/10/construction-contracting.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2021/02/ccs_logo_full.png

AbstraktMarketing2024-10-31 14:04:432025-10-18 14:24:01Construction Mistakes Your Restaurant Contractor Can Help You Avoid

https://www.calahan.com/wp-content/uploads/2024/10/construction-contracting.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2021/02/ccs_logo_full.png

AbstraktMarketing2024-10-31 14:04:432025-10-18 14:24:01Construction Mistakes Your Restaurant Contractor Can Help You Avoid https://www.calahan.com/wp-content/uploads/2024/10/walking-through-warehouse-with-clipboard.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2021/02/ccs_logo_full.png

AbstraktMarketing2024-10-31 12:52:182025-10-18 14:24:02Warehouse Building Codes That Can Make or Break Your Project

https://www.calahan.com/wp-content/uploads/2024/10/walking-through-warehouse-with-clipboard.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2021/02/ccs_logo_full.png

AbstraktMarketing2024-10-31 12:52:182025-10-18 14:24:02Warehouse Building Codes That Can Make or Break Your Project

How to Maximize Your Property’s Life With Expert Commercial Construction and Maintenance

Commercial Constuction