https://www.calahan.com/wp-content/uploads/2025/08/How-Commercial-Building-Additions-Impact-Property-Value.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2021/02/ccs_logo_full.png

AbstraktMarketing2025-08-11 10:37:342025-08-16 14:24:55How Commercial Addition Planning Impacts Property Value

https://www.calahan.com/wp-content/uploads/2025/08/How-Commercial-Building-Additions-Impact-Property-Value.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2021/02/ccs_logo_full.png

AbstraktMarketing2025-08-11 10:37:342025-08-16 14:24:55How Commercial Addition Planning Impacts Property ValuePopular Types of Warehouse Additions

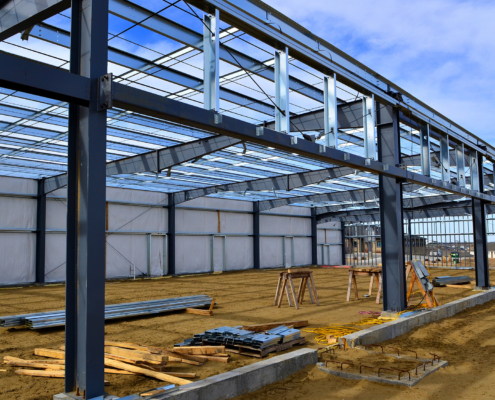

Warehouses today aren’t just storage hubs. They’re dynamic centers for logistics, distribution, and manufacturing. As your operations grow, so does the demand for more efficient space. If you’re exploring the best types of warehouse additions, you’re already taking the first step toward smarter logistics and long-term cost savings.

Understanding the Need for a Warehouse Addition

Expanding a warehouse is about much more than adding square footage. It’s about future-proofing your operations. Whether you’re managing increased inventory, introducing automation, or adjusting to new product lines, your facility’s footprint plays a crucial role in supporting your growth.

Growing Inventory Demands

As e-commerce continues to boom and supply chains evolve, many facilities find their inventory turnover increasing. Higher order volumes and just-in-case inventory models demand more rack space and staging areas. Without a warehouse addition, crowded aisles and overfilled storage zones can slow down picking and packing efficiency.

Introducing New Processes or Equipment

Bringing in new automation, such as conveyor systems or robotic picking stations, often requires significant floor space. Even manual operations like kitting or assembly may need dedicated zones. A well-planned warehouse expansion ensures you can implement these process improvements without disrupting current workflows.

Regulatory and Safety Requirements

Some industries face strict guidelines around storage clearances, egress paths, or temperature-controlled zones. If compliance updates are squeezing your existing layout, adding dedicated space might be the only way to maintain operations and meet safety codes.

Customer-Driven Fulfillment Needs

Today’s customers expect faster shipping with more SKU variety. This often means you need extra room for staging, specialized packaging, or managing returns. A warehouse building addition can help adapt your operations to stay competitive.

Common Types of Warehouse Additions

When it’s time to expand, the right design depends on your property, workflow, and operational goals. Calahan Construction, recognized industry-wide for strategic warehouse solutions, helps facilities determine the best type of addition for their long-term success.

Lateral Additions

Lateral additions, also known as side-bay expansions, are among the most practical types of warehouse additions for facilities with ample property width. By extending the building footprint sideways, you can effectively double your racking aisles or install new production lines parallel to existing operations.

This strategy keeps your workflows intuitive, minimizes structural complexities, and often leverages the same roof height and mechanical systems. It’s especially beneficial for warehouses managing diverse SKUs or requiring multiple picking zones, making lateral growth a straightforward way to boost capacity without disrupting your layout.

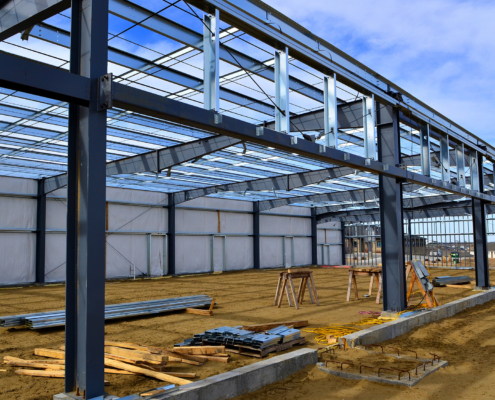

Rear Load Area Additions

Rear load area additions are perfect for facilities where shipping and receiving activities are bottlenecked. By expanding the warehouse outward from the back, you create more dock doors, staging lanes, and trailer parking spaces, dramatically improving your throughput.

This approach helps separate busy dock operations from storage and production areas, reducing internal congestion and enhancing safety. It also streamlines inbound and outbound logistics, ensuring trucks are processed faster. For many high-volume distribution centers, a rear warehouse addition is the most effective way to accommodate growing order volumes without compromising internal workflow efficiency.

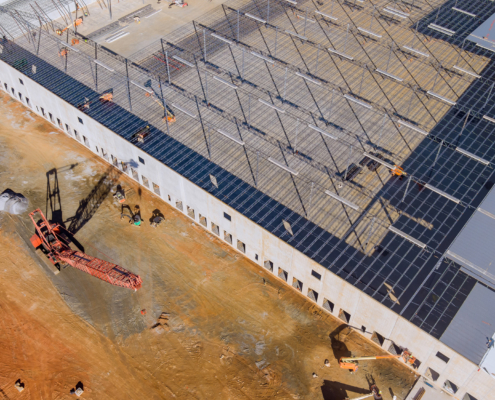

Vertical Extensions

When land is limited or zoning restricts outward growth, vertical extensions provide a smart alternative. Adding a mezzanine or constructing a full second story increases usable square footage without enlarging the building’s footprint. These types of warehouse additions are excellent for light storage, order fulfillment, or administrative offices, preserving ground-level space for forklifts and heavy machinery.

Vertical growth also optimizes existing utilities like lighting and sprinklers. For operations seeking to balance costs and functionality, going up is often the best strategy to maximize cubic volume while supporting evolving business demands.

Connected Annexes

Connected annexes offer a highly flexible way to expand, especially when you need specialized environments. Built alongside your main warehouse and linked by breezeways or enclosed corridors, these building additions can house cold storage, secure inventory rooms, or dedicated e-commerce fulfillment spaces.

This separation allows you to maintain specific temperature controls, security systems, or automated equipment without disrupting your primary facility. Annex solutions are also easier to customize for future needs. They represent one of the most adaptive types of warehouse additions, giving your operations room to evolve while staying seamlessly integrated.

Discover how Calahan Construction’s expert addition solutions can expand your warehouse’s capacity and efficiency.

Tips for Expanding Your Warehouse Space

Expanding your warehouse is a significant investment, but careful planning makes the process smoother and more cost-effective.

- Conduct a Detailed Workflow Study: By mapping current operations and bottlenecks, you’ll understand exactly where added space delivers the biggest ROI. This prevents overspending on areas that may not truly need expansion.

- Work With Experienced Warehouse Designers: Firms like Calahan Construction understand the balance between structural requirements and operational flow. They’ll identify ways to optimize new space that less experienced builders might overlook.

- Plan Utilities and Mechanicals Early: Adding square footage impacts lighting, HVAC, and sprinkler systems. Addressing these upgrades during the design phase minimizes expensive change orders later.

- Incorporate Flexibility Into the Design: Use modular racking or open layouts so you can adapt the space down the road. Business needs change, and a versatile warehouse adapts without requiring another costly build-out.

- Minimize Disruptions to Current Operations: Phasing construction or building isolated additions first can keep day-to-day productivity high while you grow. Your contractor can help sequence the work for minimal impact.

With careful planning and the right team, a warehouse expansion can transform your facility without the headaches often associated with large-scale construction.

Which Type of Warehouse Addition Is Best?

There’s no universal solution when it comes to choosing the right addition format. The decision hinges on your site conditions, building constraints, and operational priorities.

When Lateral Additions Make Sense

Side-bay expansions are perfect if your property line has room and your workflow benefits from more width. They’re ideal for adding racking aisles or parallel production lines, keeping equipment layouts simple and familiar. This approach often preserves your existing roof height and utilities, simplifying integration.

When to Opt for a Rear Addition

If your biggest challenge is dock congestion, a rear load area addition can dramatically increase your shipping and receiving throughput. It isolates loading traffic from internal workflows, improving both safety and efficiency. Facilities with a long, narrow lot often find this is the only practical way to expand.

The Case for Going Vertical

When property setbacks or surrounding developments limit your footprint, vertical warehouse additions, like mezzanines, maximize cubic volume. They’re excellent for lighter storage, packing areas, or office build-outs above the shop floor. This keeps valuable ground-level space open for forklifts and heavy equipment.

Why Choose a Connected Annex

An annex is often the best solution for specialized environmental controls or security. By building a connected yet separate space, you avoid complicating existing HVAC or fire suppression systems. This approach is especially popular for cold storage, hazardous materials, or automated pick modules.

Building Vertically vs. Horizontally

A common question for facility managers is whether to expand up or out. Each approach has unique benefits, and sometimes, the best solution combines both.

Why Vertical Expansion Is Great

Building up is often the fastest way to add space when land is scarce. A vertical warehouse addition minimizes site disturbance and can leverage existing foundations and utilities. Vertical growth may be the only practical path for facilities in urban areas or tightly zoned industrial parks.

When to Consider Vertical Expansion

You should consider mezzanines or second stories when your current processes can be layered without complicating heavy equipment movement. Light manufacturing, packaging, or administrative offices are perfect candidates for a vertical footprint.

Combining Vertical and Horizontal Growth

In many cases, a hybrid strategy works best, using lateral additions for primary workflows and adding mezzanines for support functions. Calahan Construction often guides clients toward this balanced approach, ensuring optimal use of both footprint and cubic volume.

Plan Your Warehouse Expansion With Calahan Construction

Selecting the right warehouse addition is one of the most important decisions you’ll make as a facility manager or plant engineer. From increasing racking capacity to improving loading efficiency, the impact on your logistics operation is profound. Calahan Construction specializes in evaluating operational needs and designing warehouse building addition projects that truly support long-term success.

Whether you’re exploring a warehouse expansion to stay competitive or to streamline your distribution flow, their team has the expertise to guide you through every decision. Reach out today to discover how their industry-leading approach to types of warehouse additions can elevate your facility to the next level.

Share This Post

More Like This

https://www.calahan.com/wp-content/uploads/2025/08/How-Commercial-Building-Additions-Impact-Property-Value.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2021/02/ccs_logo_full.png

AbstraktMarketing2025-08-11 10:37:342025-08-16 14:24:55How Commercial Addition Planning Impacts Property Value

https://www.calahan.com/wp-content/uploads/2025/08/How-Commercial-Building-Additions-Impact-Property-Value.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2021/02/ccs_logo_full.png

AbstraktMarketing2025-08-11 10:37:342025-08-16 14:24:55How Commercial Addition Planning Impacts Property Value https://www.calahan.com/wp-content/uploads/2025/07/Key-Considerations-Before-Starting-a-Warehouse-Expansion.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2021/02/ccs_logo_full.png

AbstraktMarketing2025-07-09 07:13:192025-08-16 14:24:56Key Considerations Before Starting a Warehouse Expansion

https://www.calahan.com/wp-content/uploads/2025/07/Key-Considerations-Before-Starting-a-Warehouse-Expansion.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2021/02/ccs_logo_full.png

AbstraktMarketing2025-07-09 07:13:192025-08-16 14:24:56Key Considerations Before Starting a Warehouse Expansion

Strategies to Reduce Downtime During Your Commercial Construction Project

Commercial Constuction, Remodel/Renovation

What You Should Know About Commercial Building Codes Before an Addition

Additions, Commercial Constuction https://www.calahan.com/wp-content/uploads/2025/01/indoor-sport-facility.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2021/02/ccs_logo_full.png

AbstraktMarketing2025-01-21 19:24:002025-08-16 14:24:59Sports Facility Construction: Everything You Need to Know

https://www.calahan.com/wp-content/uploads/2025/01/indoor-sport-facility.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2021/02/ccs_logo_full.png

AbstraktMarketing2025-01-21 19:24:002025-08-16 14:24:59Sports Facility Construction: Everything You Need to Know https://www.calahan.com/wp-content/uploads/2025/01/Worker-installing-solar-panels-on-roof.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2021/02/ccs_logo_full.png

AbstraktMarketing2025-01-20 12:04:002025-08-16 14:24:59Five Energy-Efficient Construction Techniques You Should Be Using

https://www.calahan.com/wp-content/uploads/2025/01/Worker-installing-solar-panels-on-roof.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2021/02/ccs_logo_full.png

AbstraktMarketing2025-01-20 12:04:002025-08-16 14:24:59Five Energy-Efficient Construction Techniques You Should Be Using https://www.calahan.com/wp-content/uploads/2024/10/construction-contracting.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2021/02/ccs_logo_full.png

AbstraktMarketing2024-10-31 14:04:432025-08-16 14:25:00Construction Mistakes Your Restaurant Contractor Can Help You Avoid

https://www.calahan.com/wp-content/uploads/2024/10/construction-contracting.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2021/02/ccs_logo_full.png

AbstraktMarketing2024-10-31 14:04:432025-08-16 14:25:00Construction Mistakes Your Restaurant Contractor Can Help You Avoid https://www.calahan.com/wp-content/uploads/2024/10/walking-through-warehouse-with-clipboard.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2021/02/ccs_logo_full.png

AbstraktMarketing2024-10-31 12:52:182025-08-16 14:25:01Warehouse Building Codes That Can Make or Break Your Project

https://www.calahan.com/wp-content/uploads/2024/10/walking-through-warehouse-with-clipboard.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2021/02/ccs_logo_full.png

AbstraktMarketing2024-10-31 12:52:182025-08-16 14:25:01Warehouse Building Codes That Can Make or Break Your Project

How to Maximize Your Property’s Life With Expert Commercial Construction and Maintenance

Commercial Constuction